Machining subcontractor for over 30 years!

UHMW, the most versatile plastic

About UHMW

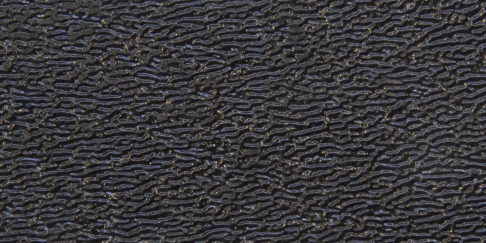

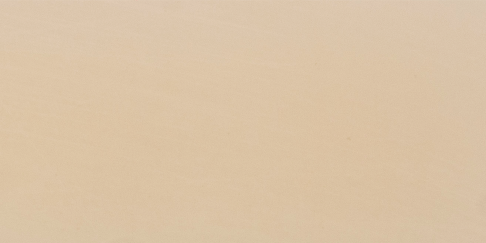

UHMW (Ultra High Molecular Weight Polyethylene) is a technical plastic known for its exceptional combination of wear resistance, low friction and durability. It is especially valued in industrial applications where friction, abrasion, and impacts are major concerns. Its high molecular weight structure provides superior mechanical properties, making it ideal for parts subjected to extreme conditions.

Trust 3D Coupe for your UHMW parts

We precisely machine UHMW to provide tailored solutions for your industrial needs. Whether it’s for complex technical parts or standard components, our expertise ensures a high-quality final product. Contact us to discuss your project!

UHMW Features

Mechanical Performance

- Excellent abrasion resistance: ideal for high-friction applications like chain guides and slide rails.

- High impact resistance: absorbs shocks without cracking, perfect for high mechanical stress environments.

- Low coefficient of friction: reduces wear and heat buildup, extending component lifespan.

Thermal Performance

- Operating temperature from -200°C to 80°C: remains stable under extreme conditions.

- Good thermal insulation: does not conduct heat, useful for insulating applications.

Chemical Performance

- Chemical resistance: withstands solvents, diluted acids, and alkalis without degrading.

- Moisture-proof: does not swell or degrade in the presence of water.

Practicality

- Easy to machine: suitable for milling, turning, and cutting.

- Self-lubricating: minimizes maintenance and the need for external lubricants.

- Lightweight: easy to handle and integrate into various systems.

Utilization of UHMW

UHMW is primarily used in manufacturing, food, and mechanical industries. It is favored for the production of conveyor guides, bearings, slides, and components exposed to abrasive conditions or high mechanical stresses. Its durability and low friction make it an indispensable choice for demanding industrial applications.

FAQ and Comparisons

What is the difference between UHMW and PTFE?

Both UHMW and PTFE are low‐friction plastics, but PTFE can withstand much higher temperatures and offers better chemical resistance. In contrast, UHMW is more impact‐resistant and cost‐effective.

Is UHMW food-grade?

Yes, UHMW is often used in the food industry because it is chemically inert, moisture‐resistant, and FDA‐approved for food contact.

Can UHMW be welded?

Unlike some plastics, UHMW is very difficult to weld due to its molecular structure. It is preferable to use mechanical fasteners or specialized adhesives.

Is UHMW UV-resistant?

Standard UHMW is sensitive to UV and can degrade over time with prolonged exposure. UV‐stabilized versions are available for better outdoor durability.

UHMW vs Nylon: Which one to choose?

UHMW offers better abrasion resistance and lower friction, making it ideal for sliding applications. Nylon, on the other hand, has better heat resistance and supports heavier loads.

Can UHMW be painted or glued?

Painting or gluing UHMW is very difficult due to its non-adhesive surface. Specific surface treatments may be necessary to improve adhesion.

UHMW vs Acetal: Which one to choose?

UHMW is more flexible, more impact and abrasion resistant, whereas Acetal is stiffer, more dimensionally stable, and supports higher loads.

UHMW Machining Specialists

We are experts in machining UHMW for custom industrial applications. Trust us with your needs for precise and high-performance technical components!

We drive our clients’ growth through smart, customized subcontracting partnerships.