Machining subcontractor for over 30 years!

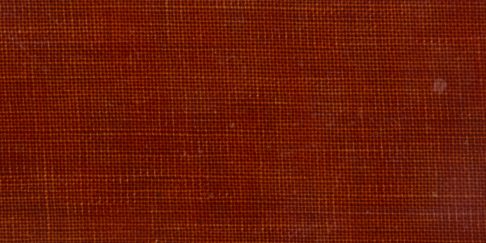

Phenolic, a robust and resistant composite

About phenolic

Phenolic is a composite material resulting from the polymerization of phenolic resins reinforced with paper, cotton fabric, or fiberglass. It is distinguished by its robustness, dimensional stability, and ability to withstand extreme conditions. Its excellent strength-to-weight ratio makes it an ideal choice for machining parts designed for the electrical, aerospace, and mechanical industries.

Expertise in machining phenolic

At 3D Coupe, we leverage our expertise in machining composites to provide precise and high-performance phenolic parts. Contact us to discuss your specific needs!

Characteristics of phenolic

Mechanical performance

- High wear resistance: its laminated composition gives it excellent durability against abrasion and mechanical stresses.

- Rigidity and dimensional stability: it retains its physical properties even under heavy load, limiting deformation.

Thermal performance

- Good high-temperature resistance: capable of withstanding temperatures up to 250°C without significant deterioration.

- Low thermal expansion coefficient: minimizes dimensional changes with temperature variations.

Chemical performance

- Excellent solvent resistance: withstands oils, greases, and hydrocarbons well, making it an ideal material.

- Good resistance to aggressive chemicals: suitable for industrial environments exposed to corrosive chemicals.

Practicality

- Ease of machining: can be easily worked with conventional equipment, offering high precision in the production of complex parts.

- Good electrical insulator: recommended for applications requiring effective electrical insulation.

Use of phenolic

Phenolic is highly valued for electrical and mechanical applications. It is used in the manufacture of insulating panels, aerospace structural parts, gear supports, and components for the electrical industry thanks to its excellent insulating and resistant properties.

FAQ and Comparisons

What is the difference between phenolic and Bakelite?

Bakelite is a type of phenolic resin, but the term is often used to designate the earliest versions of thermosetting plastics. Modern phenolic is a more advanced composite, reinforced with various materials to enhance its durability and performance.

Phenolic vs G10: which one to choose?

G10, a composite made of epoxy resin and fiberglass, offers better moisture resistance and greater robustness than phenolic. However, phenolic is easier to machine and has a lower manufacturing cost.

Is phenolic flammable?

Phenolic has good fire resistance and emits little smoke in the event of combustion. However, it can be treated to further enhance its fire-retardant properties.

Can phenolic be used outdoors?

Although phenolic offers good resistance to chemicals, it can degrade with prolonged exposure to UV and humidity. The application of a protective coating is recommended for extended outdoor use.

How to machine phenolic without damaging tools?

Machining phenolic can quickly wear out tools due to its rigidity. Using carbide tools and ensuring proper dust extraction are essential to optimize the process and extend tool lifespan.

Specialists in phenolic machining

Our expertise in composite machining enables us to produce high-precision phenolic parts. Trust us with your projects for custom and high-performance solutions!

We drive our clients’ growth through smart, customized subcontracting partnerships.