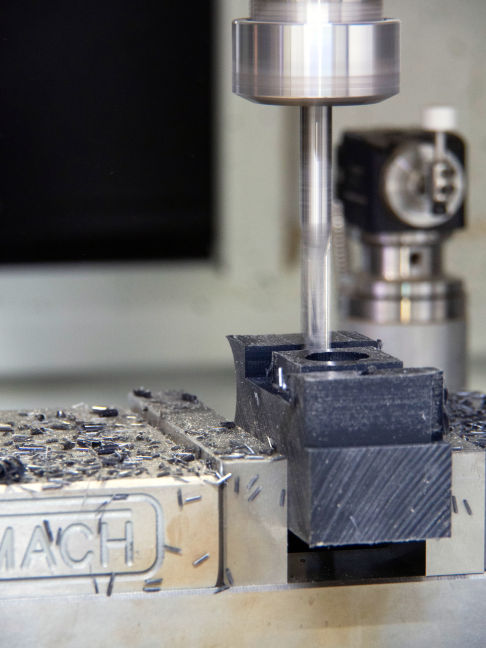

Machining subcontractor for over 30 years!

Thermoforming: guaranteed quality and performance

Shape your ideas with an experienced partner. Precise and cost-effective solutions for your most demanding projects.

About thermoforming at 3D Coupe

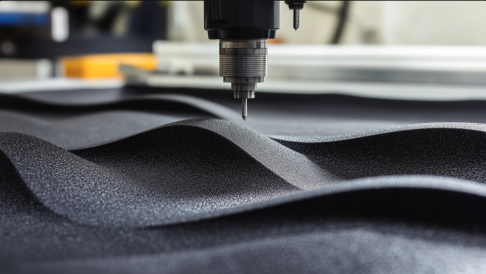

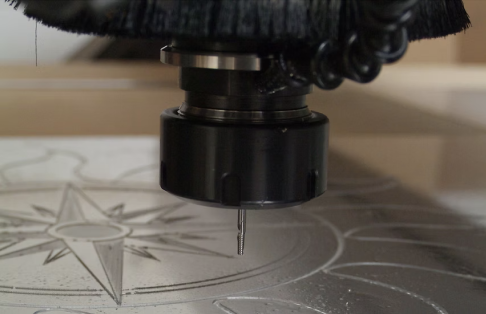

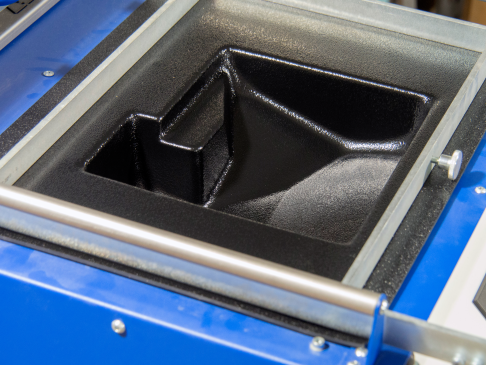

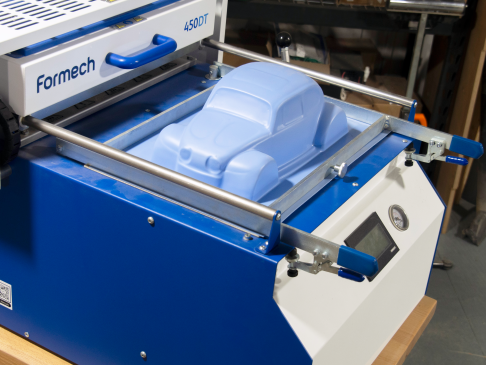

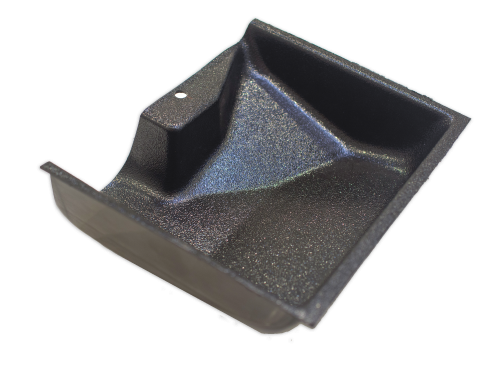

Thermoforming is a precision technique that involves heating a thermoplastic sheet until it becomes pliable. The material is then laid on a mold to give it the desired shape, and the residual air is evacuated with vacuum. After cooling and solidification, the part undergoes a cutting and finishing process to obtain the final result. At 3D Coupe, we guarantee precise results thanks to our state-of-the-art equipment and our in-depth expertise, whether for technical parts or complex industrial components.

Production process

Thermoforming: a strategic partnership to optimize your production

At 3D Coupe, we rely on transparent and sustainable collaborations to maximize the performance of your projects. Through continuous communication, we adjust each step of the process according to your needs. Our proactive approach allows us to optimize material costs and develop tailor-made growth strategies, ensuring efficient and competitive production.

Satisfied Clients

FAQ

What types of materials can be used in thermoforming?

We work with a wide range of thermoplastics, including acrylic (plexiglass), polyethylene, nylon, Nyloil®, Teflon, UHMW, and many others. The material choice is tailored to your specific requirements in terms of strength, flexibility, and final application.

What are the advantages of thermoforming compared to other manufacturing processes?

Thermoforming offers short manufacturing lead times, reduced mold costs, and great flexibility in part design, making it ideal for production runs of various sizes.

What is the difference between vacuum thermoforming and pressure thermoforming?

Vacuum thermoforming uses suction to pull the plastic sheet against the mold, whereas pressure thermoforming applies additional air pressure to achieve a more precise level of detail.

3D Coupe, your expert in custom machining

Are you looking for a reliable partner for manufacturing your parts? We are here to advise you and offer solutions tailored to your needs. Contact us today to discuss your project and get a personalized quote!

We drive our clients’ growth through smart, customized subcontracting partnerships.

Contact us easily

About us

Discover our materials

Need an expert in thermoforming?

At 3D Coupe, we master the art of thermoforming to transform your ideas into high-quality finished products. Our dedicated team is ready to collaborate with you to optimize your production and meet your specific needs!