Machining subcontractor for over 30 years!

Plastic bending: custom expertise and innovation

An expert partner for all your projects. Benefit from personalized support to succeed in your productions.

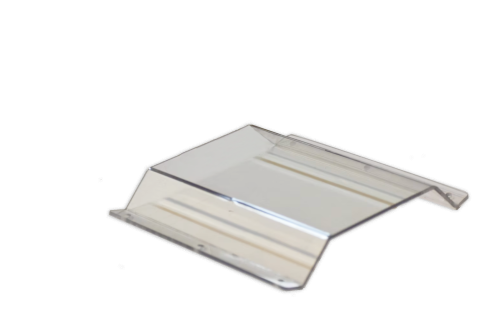

About Plastic Folding at 3D Coupe

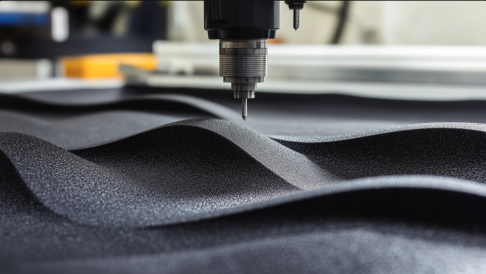

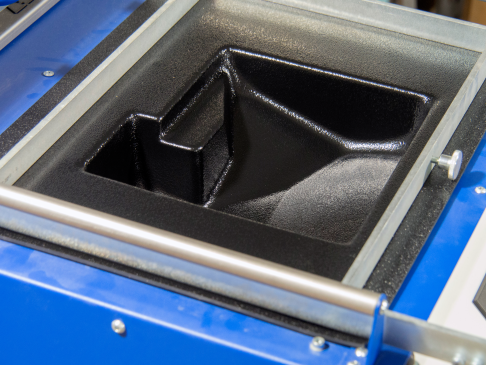

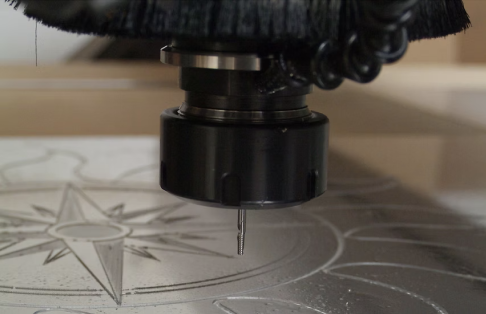

Plastic folding is an effective solution for shaping durable parts while avoiding complex assemblies. At 3D Coupe, we master advanced thermal bending techniques thanks to our uniquely automated plastic bender in Canada, ensuring clean and consistent results on a wide variety of plastics. Our processes adapt to the requirements of many sectors, from signage and technical packaging to custom components.

Production Process

A Partner Committed to the Success of Your Projects

At 3D Coupe, we put our expertise at the service of your production with an approach based on transparency, adaptability, and cost optimization. More than just a service provider, we are a strategic partner who supports you in optimizing your processes and efficiently managing your resources.

Satisfied Clients

Frequently Asked Questions

What types of plastics can be bent?

We work with a wide range of plastics and engineering plastics, including acrylic, polycarbonate, ABS, HDPE, and PETG. The choice of material depends on your application and the desired properties (impact resistance, transparency, flexibility, etc.).

What are the possible dimensional tolerances with plastic bending?

Tolerances vary depending on the type of plastic and its thickness, but we guarantee high precision, typically around ±0.5 mm.

Does bending affect the properties of plastic?

No, when bending is done correctly, the plastic's mechanical properties are preserved. Our controlled heating and cooling techniques prevent any excessive or weakened deformation.

What is the difference between hot and cold bending?

Hot bending uses a heat source to locally soften the plastic before bending it, while cold bending is only possible for certain highly flexible plastics. Hot bending is the most commonly used method to ensure clean and long-lasting results.

Can complex bends be performed on a single piece?

Yes, we can perform multiple bends on a single piece with high precision, allowing the creation of three-dimensional structures without assembly.

What are the production lead times for plastic bending?

Lead times vary depending on production volume and the complexity of the parts, but we optimize our processes to ensure fast and reliable delivery.

3D Coupe, Your Expert in Custom Plastic Bending

As the undisputed leader in digital cutting, we put our expertise at your service for precise and durable parts. Contact us to discuss your project and get a solution tailored to your needs!

We drive our clients’ growth through smart, customized subcontracting partnerships.