Machining subcontractor for over 30 years!

Machining shop

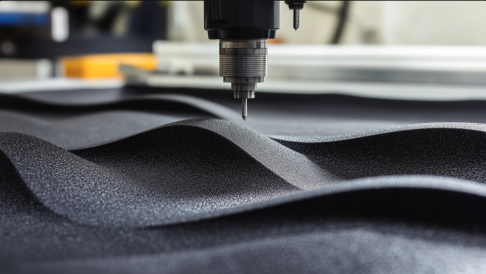

Plastic, wood and non-ferrous metals

More than 12 areas of expertise under one roof. We can help you achieve your production goals.

We create strategic and sustainable partnerships

We provide you with specialized machining workshops capable of turning your designs into high-precision parts. Thanks to our expertise in industrial subcontracting, we work with a wide variety of materials from plastic to non-ferrous metal, including rubber, wood, and foam.

We position ourselves as a true business partner, focusing on transparency, quality, and efficiency. Whether you need small or large series production, our solutions are designed to optimize your costs while ensuring impeccable finishing.

We drive our clients’ growth through smart, customized subcontracting partnerships.

Production Process

Strategic Partnership in Industrial Subcontracting

We believe in the value of long-term partnerships. By collaborating with us, you benefit from complete transparency regarding the cost of materials and manufacturing processes. Our approach based on exchange and communication allows us to optimize your production and support your growth.

Satisfied Clients

We drive our clients’ growth through smart, customized subcontracting partnerships.

Frequently Asked Questions

Which materials can you machine in your workshops?

We work with a wide range of materials, including plastic, rubber, non-ferrous metals, wood, and foam. Each material requires a specific approach to guarantee optimal machining. Visit the 'Our Materials' page for more information

Do you offer prototyping services?

Yes, we can produce functional prototypes before series production to validate your designs and adjust parameters if needed.

What types of machines do you use?

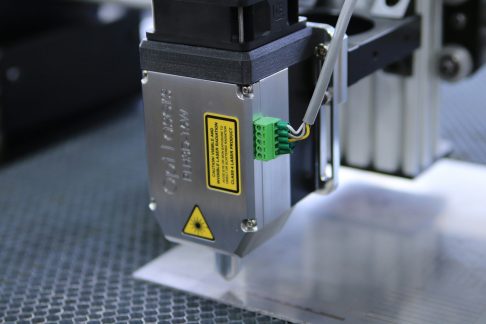

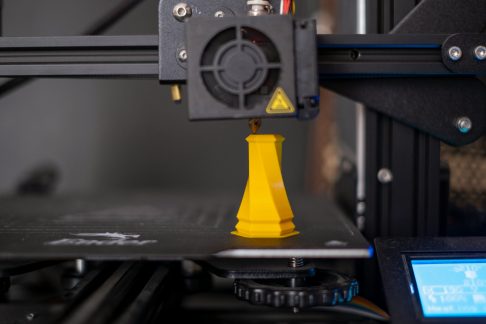

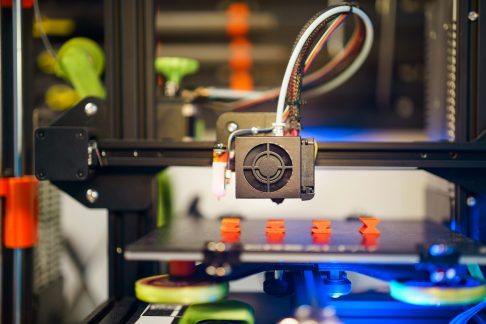

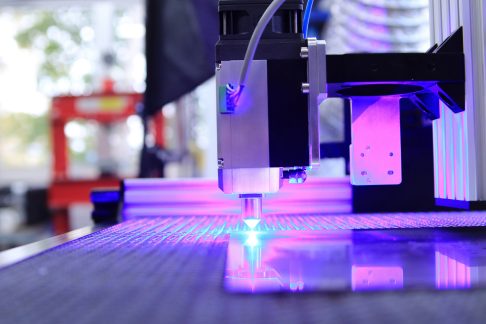

Our workshops are equipped with a 5-axis simultaneous machining center, a 3-axis cutting center, CNC milling machines, digital lathes, a unique automated plastic bending machine in Canada, as well as specialized equipment such as laser cutting and engraving machines, a next-generation plastic welding machine and state-of-the-art 3D printers.

We also use an ERP system and advanced CAD/CAM software to ensure maximum precision and efficiency.

What is your production capacity?

We can handle both small series and large-scale productions while maintaining high quality standards.

How do you ensure the quality of your machined parts?

We apply strict controls at every stage of the machining process, including dimensional checks and strength tests, to ensure products that meet your expectations.

What are your delivery times?

Our delivery times vary depending on the order's complexity and volume, but we are committed to meeting the agreed deadlines through rigorous planning.

Can you work in co-development with our engineers?

Yes, we work closely with your technical teams to optimize part design.

Entrust us with your machining projects!

Our experts specialize in transforming plastic, metal, wood, rubber, and foam. Contact us today to discuss your project.

AI Comparison

Optimize your choices with our advanced AI tool. Quickly compare material properties and identify the best solution for your project. Save time, reduce costs, and make informed decisions in seconds.