Machining subcontractor for over 30 years!

Over 12 areas of expertise under one roof. We can help you achieve your production goals.

Reduce Your Part Manufacturing Costs

In a context where industrial competitiveness continues to intensify, every penny counts. Reducing the manufacturing costs of your parts without sacrificing quality or extending lead times has become an essential strategic lever. For manufacturing companies, outsourcing represents an excellent way to optimize their operations - provided they make the right choices. In this article, we explore five concrete ways to reduce your manufacturing costs while ensuring performance and reliability.

Current challenges in outsourced manufacturing

The manufacturing industry is undergoing a period of accelerated transformation. Between the rising cost of raw materials, tensions in the global supply chain and the constant pressure to deliver faster, better and cheaper, companies are facing unprecedented challenges.

One of the major challenges: controlling production costs, especially in an outsourcing context. On one hand, outsourcing allows companies to benefit from specialized resources and state-of-the-art equipment without heavy financial investments. On the other, it requires increased rigor in communication, quality control and process optimization.

In the face of these challenges, companies that manage to combine agility, innovation and strategic partnership management stand out from the competition.

Trends to watch for better manufacturing

Industrial companies seeking to reduce their manufacturing costs are increasingly adopting intelligent and adaptive practices. Here are the key trends to watch:

1. Design to cost

The design of parts plays a fundamental role in cost reduction. We are witnessing a rise in the “design to cost” approach, an approach that integrates budget constraints from the design phase. Engineers work closely with subcontractors to create parts that are quicker to produce, easier to assemble and require less raw material.

2. Digitalization of production

Digital tools, such as simulation software, optimization programs or MES (Manufacturing Execution System), allow you to monitor production in real time, quickly identify failures and reduce waste. Digital technology is also an asset for refining planning and shifting more efficiently to a “just in time” mode.

3. Intelligent automation

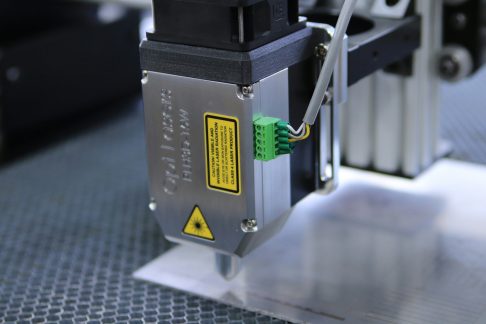

Robots, CNC machining centers and self-adjusting technologies enable subcontractors to boost productivity. For companies that design their parts with automation in mind, this means reduced costs, shorter lead times and more consistent quality.

4. Proximity partnerships

Rather than multiplying suppliers, many companies choose to build lasting relationships with a few trusted subcontractors who can develop their skills over time. This promotes production coherence, reduces logistics costs and improves responsiveness in unforeseen situations.

Practical tips to reduce your manufacturing costs

1. Simplify the design of parts

A part that is simple to manufacture always costs less than a complex one. By opting for simplified geometries, you reduce the number of required tools, manual handling and potential errors.

Moreover, excessively tight tolerances or unnecessary finishing requirements (for example, a mirror polish on a non-visible surface) can quickly increase costs. Work with your subcontractors to define technical specifications that are both functional and economical.

2. Optimize your production chain

Every machine stoppage, every scrap and every surplus of material represents a net loss. It is therefore essential to have a comprehensive view of the production chain.

- Implement preventive maintenance to avoid costly breakdowns.

- Use production management software to improve yield and limit idle inventories.

- Embrace a “just in time” approach that allows you to produce only what is necessary, when it is needed, thereby reducing storage costs.

3. Outsource to specialized subcontractors

Specialized subcontractors generally have state-of-the-art equipment, experienced teams and optimized processes. By entrusting them with your parts, you avoid heavy investments (CNC machines, specialized molds, control systems) and reduce your fixed costs.

Even better, the best subcontractors benefit from significant purchasing volumes of raw materials, enabling them to offer you competitive prices. Choosing a strategic partner can therefore have a direct and immediate impact on your margin.

4. Embrace automation

Adapt your designs to facilitate automatic machining:

- Regular shapes;

- Few sharp edges;

- Materials compatible with digital machining.

By reducing human intervention, you decrease the risks of error, rework and delays. More and more subcontractors today are integrating advanced robotic or digital solutions – take advantage of this to boost your efficiency.

5. Negotiate with your suppliers and subcontractors

The conditions you secure today are not set in stone. There is always room for improvement:

- Compare several suppliers for your materials;

- Participate in trade shows or B2B meetings to discover new partners;

- Regularly review your agreements to align with market realities.

With a proactive approach and strategic monitoring, you can negotiate a better quality-price ratio while maintaining the quality of your finished products.

Explore innovative solutions to stay competitive

Reducing manufacturing costs should never come at the expense of quality or customer relationships. By adopting intelligent practices and collaborating with subcontractors who share your objectives, you can transform your operations into a lever for sustainable growth.

At 3D Coupe, we believe that every company deserves a trusted partner, capable of adapting to its needs, delivering on time and contributing to its efficiency goals. Whether it is for machining plastic, rubber, foam or non-ferrous metals, we combine technical expertise, transparency and flexibility to help you go further.

Contact us today to explore solutions tailored to your reality.

FAQ

What machining services do you offer?

See all services

What materials do you work with?

Plastics, foams, wood, and non-ferrous metals

I want to optimize my production costs

By working transparently and identifying mutually beneficial opportunities, we can build a growth-focused partnership and significantly reduce material and production costs.